Home / CNC Tools / End Mills / Double Flute End Mills / Long Reach Double Flute Ball Nose End Mill

Long Reach Double Flute Ball Nose End Mill

Add to FavoritesAlready In Favorites

Add to Favorites

For applications requiring 3D contouring in deep pockets, long-reach tools are designed for these situations. This is achieved by reducing the diameter above the cutting edge allowing clearance between the tool and the wall when machining deeper cuts. These tools are best suited for these special circumstances – shorter are recommended for improved performance. These tools are perfect for aluminum, brass, plastics, exotic composites and hard alloys.

Ballnose end mills are designed for machining three dimensional contours and five-axis parts. The tools are ideal because the rounded cutting edge offers very little chipping and smooth surfaces. These long-life, micro-grain carbide tools are available in various cutting diameters and lengths, shank diameters, coatings and geometries for specialty applications.

DATRON’s unique CNC cutting tools are made with a proprietary process:

- We use high quality micro-grain carbide to provide superior tool life and long-term savings

- A multi-stage grinding process delivers extra sharp, polished edges for burr-free machining, reducing or eliminating the need to hand-finish parts

- Patented tool geometries that decrease cycle times, improve finishes and boost productivity

Check out this video on our tools: https://www.youtube.com/watch?v=56ZsM_h13Vc

Article #:

See Options Below

Categories Ball Nose End Mills, Double Flute End Mills

Tags 3D Surfacing, Deep Milling

Long Reach Double Flute Ball Nose End Mill

$62.05 – $108.76Price range: $62.05 through $108.76

Filter Table

Cutting Diameter (D1)

Shank (D2)

D3

Length (L1)

Cutting Depth (L2)

L3

Operations

Radius (R)

Showing 1 – 9 of 9 results Showing all 9 results Showing the single result No results found

Sort by

Filters Sort results

Reset Apply

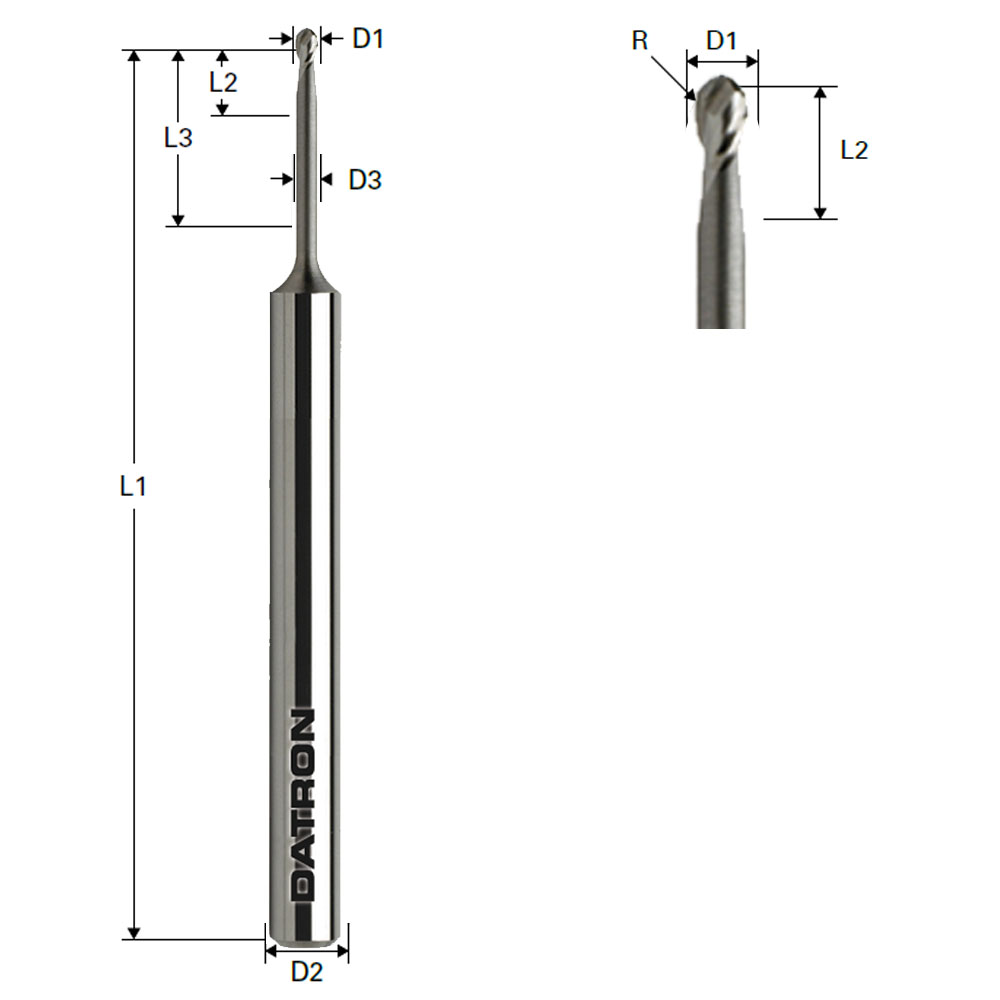

Article # | The number of cutting flutes in the tool determine how much material can be removed per rotation. For high speed, bulk material removal, single and double flute are recommended. Higher flutes will produce finer finishes, but may require a lower RPM than single flute mills. Flutes | D1 Nominal cutting diameter of the tool Cutting Diameter | D1 Nominal cutting diameter of the tool Clamping Diameter | D2 Shank diameter where the tool is in contact with the holder. D2 diameter can be too large for some machine spindles and smaller diameters may need an adapter to be used with spindles. Shank | D2 Shank diameter where the tool is in contact with the holder. D2 diameter can be too large for some machine spindles and smaller diameters may need an adapter to be used with spindles. (D2) | D3= Toric cut diameter is the relief made above the cutting flutes on the neck to allow a tool to have longer reach when milling deeper features. Also known as extended reach. (D3) | D3= Toric cut diameter is the relief made above the cutting flutes on the neck to allow a tool to have longer reach when milling deeper features. Also known as extended reach. Interface | L1 L1 is the total length of the tool from tip to base. Length | L1 L1 is the total length of the tool from tip to base. (L1) | L2 L2 is the length of the usable cutting edge of the tool. This is only the flutes. Also known as flute length. This determines the amount (depth) of material that can be removed per pass. Cutting Depth | L2 L2 is the length of the usable cutting edge of the tool. This is only the flutes. Also known as flute length. This determines the amount (depth) of material that can be removed per pass. (L2) | L3 L3= This is the overall reach a tool can be used. Flute plus any relief made by reducing the diameter in D3. AKA known as reach Reach | Radius of the cutting tip/nose. Edge Radius | Angle A= angle of a cutting edge. Drills, engraving tools and countersink tools aka point angle. A | Price | Availability | Size | Quantity | Add to cart | Waitlist | ||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 00782004 | 2 | 0.4mm | 3mm | 0.35mm | 39mm | 0.6mm | 2mm | 0.2mm | $86.92 | 4 in stock | Max: 4 Min: 1 Step: 1 | | ||||||||||||

| 00782005 | 2 | 0.5mm | 3mm | 0.45mm | 39mm | 0.75mm | 4mm | 0.25mm | $86.92 | 10 in stock | Max: 10 Min: 1 Step: 1 | | ||||||||||||

| 00782008 | 2 | 0.8mm | 3mm | 0.75mm | 39mm | 1.2mm | 6mm | 0.4mm | $97.94 | 25 in stock | Max: 25 Min: 1 Step: 1 | | ||||||||||||

| 00782011 | 2 | 1mm | 3mm | 0.95mm | 39mm | 3mm | 9mm | 0.5mm | $97.94 | 15 in stock | Max: 15 Min: 1 Step: 1 | | ||||||||||||

| 00782020 | 2 | 2mm | 3mm | 1.95mm | 39mm | 3mm | 12mm | 1mm | $108.76 | 10 in stock | Max: 10 Min: 1 Step: 1 | | ||||||||||||

| 0078502 | 2 | 2mm | 6mm | 1.8mm | 75mm | 5mm | 20mm | 1mm | $62.05 | 4 in stock | Max: 4 Min: 1 Step: 1 | | ||||||||||||

| 0078503 | 2 | 3mm | 6mm | 2.8mm | 75mm | 6mm | 20mm | 1.5mm | $62.05 | 5 in stock | Max: 5 Min: 1 Step: 1 | | ||||||||||||

| 0078506 | 2 | 6mm | 6mm | 5.8mm | 100mm | 20mm | 40mm | 3mm | $70.74 | 18 in stock | Max: 18 Min: 1 Step: 1 | | ||||||||||||

| 0078508 | 2 | 8mm | 8mm | 7.8mm | 100mm | 20mm | 40mm | 4mm | $79.48 | 13 in stock | Max: 13 Min: 1 Step: 1 | |

Dimensions: D1=20 mm D3=18.5mm L2=10mm L3=60mm

Related products

-

Double Flute Ball Nose End Mill

$46.90 – $90.46Price range: $46.90 through $90.46 Select options This product has multiple variants. The options may be chosen on the product page -

Double Flute End Mill

$17.60 – $151.28Price range: $17.60 through $151.28 Select options This product has multiple variants. The options may be chosen on the product page -

Single Flute Ball Nose End Mill

$60.80 – $91.30Price range: $60.80 through $91.30 Select options This product has multiple variants. The options may be chosen on the product page -

Polished Single Flute Ball Nose End Mill

$96.13 Select options This product has multiple variants. The options may be chosen on the product page -

Coated Long Reach Four Flute End Mill with Edge Radius

$77.63 – $86.34Price range: $77.63 through $86.34 Select options This product has multiple variants. The options may be chosen on the product page