CNC Mills & Cutting Tools

What Makes DATRON CNC Tools the Best for Precision, High-Speed Milling?

High-quality micro-grain carbide to provide superior tool life

Precision engineered to achieve superior cutting and finish

Designed for high-speed milling

A multi-stage grinding process delivers extra sharp, polished edges for burr-free machining, reducing or eliminating the need to hand-finish parts

Patented tool geometries that decrease cycle times, improve finishes, and boost productivity

Universal fit and compatible with most CNC machines

End mills are the most commonly used and versatile CNC cutting tools. Single and double flute end mills are great for high-speed bulk material removal and general milling. Higher flutes will produce a finer finish and remove more material per rotation.

Single Flute End Mills

DATRON Single Flute End Mills are designed for high-speed machining and high-volume material removal. This tool’s geometry and large chip channel effectively remove chips allowing for higher feed rates and shorter cycle times.

Double Flute End Mills

From plastic to aluminum, DATRON Double Flute End Mills provide high-quality surface finishes. The smaller chip loads and extra cutting edges (compared to a single flute) result in less tool deflection and chatter.

Triple Flute End Mills

Multi-flutes for ultra smooth finishes.

Specialty End Mills

For those tricky undercuts, DATRON has a dovetail milling tool and t-slot mill. The dovetail milling tool can bevel and deburr the underside of a part, removing the need to flip the part over for a second operation.

Ball Nose End Mills

DATRON Ball Nose End Mills are excellent for milling smooth 3D surfaces, even on complex shapes. The rounded cutting edge (and being able to use the full radius of the tool) makes it easy to cut material at any angle.

Our multi-fluted, angled cutters produce a high-quality edge finish on soft metals, plastics, and composites. DATRON’s line of countersink and chamfer tools can drill a countersink in a single plunge or mill a superb chamfered edge.

Countersink/Chamfer Mill

For applications requiring a countersunk hole, these multi-fluted angled tools machine the conical shape with excellent surface finishes. The hole should be drilled or machined prior to the plunge. These tools are perfect for aluminum, brass, plastics, exotic composites and any soft metals. They are not recommended for steel.

Milling Countersink with Edge Radius

Mill both a hole and countersink at one time without an extra tool change. The combination tool has a single flute end mill built into the bottom of the angled cutter, so you do not have to pre-drill or mill the hole prior. These tools are perfect for aluminum, brass, plastics, exotic composites and any soft metals. They are not recommended for steel.

Polished Countersink/Chamfer Mill

For countersinking in plastics and acrylics, these polished angled tools machine the conical shape with near-translucent surface finishes. The hole should be drilled or machined prior to the plunge. These tools are designed for plastics and using them in metals will dull the edges quickly.

Foam Countersink

For countersinking and chamfering operations in foam, these tools are excellent for machining the conical shape or beveled edges. These tools are designed for foam and should not be used with other materials.

External Radius

External Radius Mill

From a slight .5mm radius to a larger 6mm radius, we offer a line of multi-flute cutters than can machine these types of rounded edges. The tools can machine in all three directions and provide excellent surface finishes. These tools are designed for aluminum, brass, plastics, exotic composites and any soft metals. They are not recommended for steel.

Polished External Radius End Mill

For machining radius edges on acrylics and plastics, DATRON offers a line of polished cutters. The 1mm – 3mm range of radius end mills will provide excellent, near-translucent surface finishes. These tools are designed for machining plastics in just X & Y directions. Machining metals or plunging will quickly dull the extra sharp edges.

Deburring End Mill

For removing burrs and sharp edges on steel parts, this specially ground, uncoated tool is for this application only. The .3mm (.012”) radius two-fluted cutter is designed to machine in X & Y directions.

Face Mills

DATRON Face Mills are ideal for truing up your materials and providing a superior surface finish. Designed for high spindle speeds and fast feed rates, their wide cutting edges are quick and effective in removing a skim coat off material.

Stepped Single Flute End Mill

A stepped tool means the cutting diameter is larger than the shank diameter. This facilitates a larger cutting diameter for surfacing with spindles using smaller collet sizes. This general-purpose face milling tool is good for surfacing, light depth cuts or heavier cuts with higher torque spindles. The tool is balanced and strong, producing minimal vibrations which translates into good surface finishes. These tools are perfect for aluminum, brass, plastics and exotic composites.

Stepped Double Flute End Mill

A stepped tool means the cutting diameter is larger than the shank diameter. This facilitates a larger cutting diameter for surfacing with spindles using smaller collet sizes. This general-purpose face milling tool is good for surfacing, light depth cuts or heavier cuts with higher torque spindles. The tool is balanced and strong, producing minimal vibrations which translates into good surface finishes. These tools are perfect for aluminum, brass, plastics and exotic composites.

MCD-Monocrysalline Diamond Tool

Monocrystalline Diamond (MCD for short) face mills are the ideal choice for achieving the best possible surface finish in non-ferrous materials. Designed for finishing operations only, the MCD face mill features a hand-ground, singular diamond, along with a balanced, heavy carbide body. The combination of the two provides unparalleled finish, capable of providing mirrored finishes in brass and aluminum, and optically clear finish in polycarbonate and acrylic.

Monoblock HSK E-25

The Monoblock tool is a standard HSK E-25 tool holder configured with two changeable cutting inserts. The larger cutting diameter makes it ideal for surfacing with spindles using the HSK format. This general-purpose face milling tool is good for surfacing and shallow cutting depths. It is not designed for heavy material removal. The tool is balanced and strong, producing minimal vibrations which translates into excellent surface finishes. Notes: Extra screws and screwdriver are included. The cutting inserts are extra.

Engravers

DATRON offers tools with a variety of engraving profiles to meet your application needs. The engravers with a wider V-shape tip offer increased tool strength, and the narrower tips allow for finer detail.

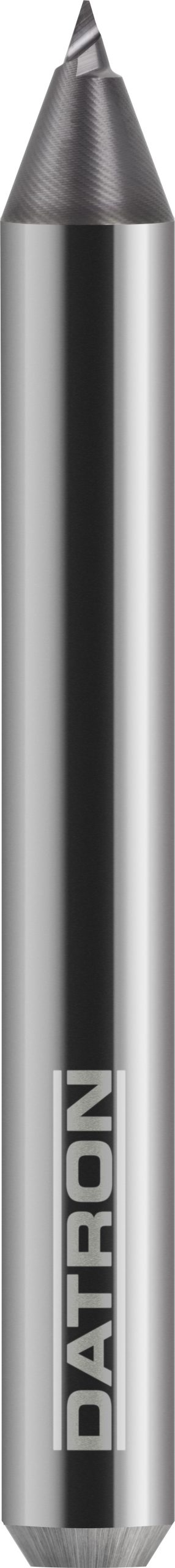

Standard Engraving Tool

The standard engraving tool is ground specifically for a wide range of materials. These materials include: plastics, aluminum, bronze, brass, copper, wood and acrylic. The carbide cutters can be re-sharpened using a proper cutter grinder. This service is not offered by DATRON.

Balanced Standard Engraving Tool

This engraving tool has an extra grinding process that balances the tool. This reduces harmonics, improves surface finishes and is better for spindles when using higher RPM’s. The tools can be used for a wide range of materials including: plastics, aluminum, bronze, brass, copper, wood and acrylic. The carbide cutters can be re-sharpened using a proper cutter grinder. This service is not offered by DATRON.

Coated Standard Engraving Tool

The standard engraving tool is ground specifically for a wide range of materials. These materials include: plastics, aluminum, bronze, brass, copper, wood and acrylic. The carbide cutters can be re-sharpened using a proper cutter grinder. This service is not offered by DATRON.

Steel Machining - Standard Engraving Tool

The standard engraving tool is ground specifically for engraving steel. The relief angle on the back of the tool is minimal offering better strength and stability. The uncoated carbide cutter can be re-sharpened using a proper cutter grinder. This service is not offered by DATRON.

Thread Mills

DATRON Thread Mills offers advantages over tapping, like being able to control the fit, adjust the thread size, and create custom threads. We have a wide range of micro-grain carbide tools that can create thread sizes as small as 1-64 UNC or M1 Metric threads.

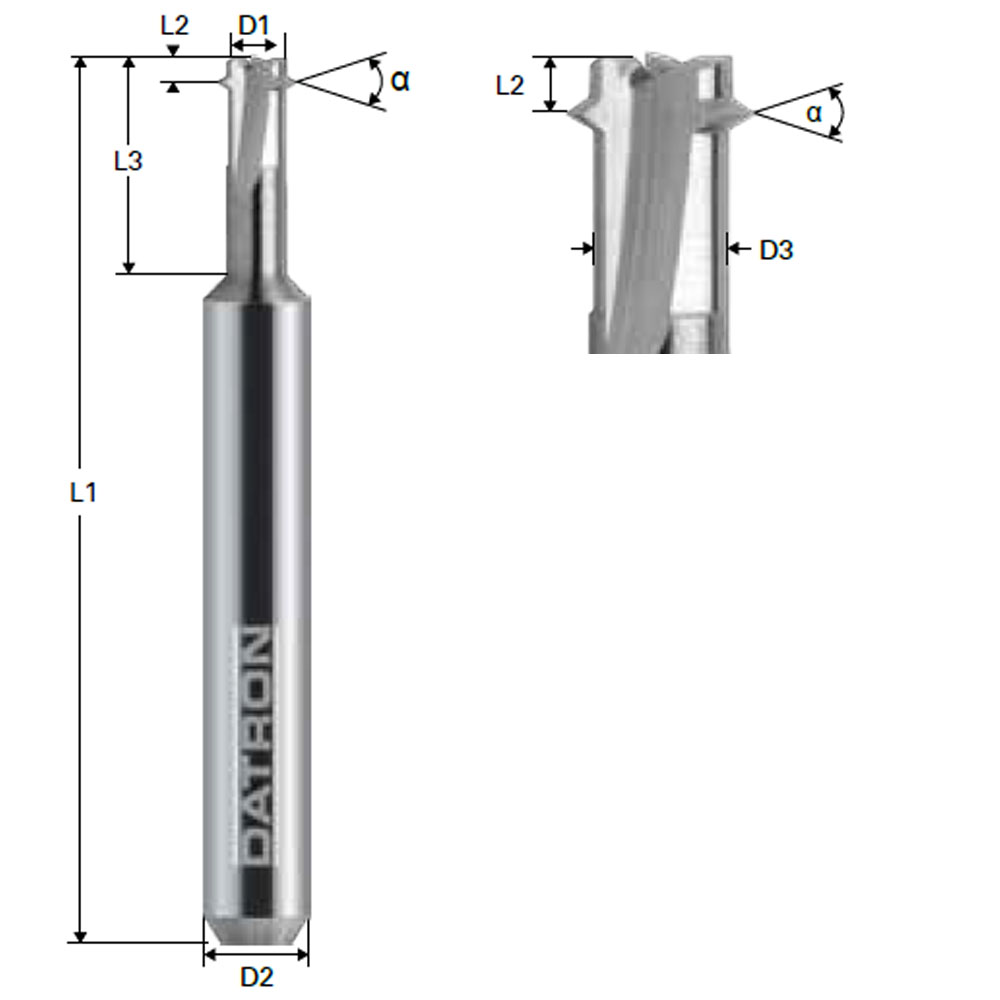

Thread Mill

For machining threads, these thread mills cover both ranges of Metric and Imperial sizes. This design of thread mills require you to mill or drill a hole prior to threading. These tools are perfect for aluminum, brass, plastics, exotic composites and any soft metals. They are not recommended for steel. We offer a wide range of micro-grain carbide tools that can create thread sizes as small as 1-64 UNC or M1 Metric threads.

Multi Thread Mill

The multi thread mill can thread a hole more quickly than a standard thread mill. The multiple cutting teeth achieve a very good quality, exact thread in just one revolution. They are not recommended for steel.

Milling Thread Mill

For machining threads, these milling thread mills cover both ranges of Metric and Imperial sizes. This design of thread mill has a combination end mill and thread mill, so you can mill and thread the hole at the same time. Because of the built-in end mill, threading blind holes can have limitations. These tools are perfect for aluminum, brass, plastics, exotic composites and any soft metals. They are not recommended for steel.

Drills

For precision holes, using a drill compared to helixing with an end mill is a better solution. A drilled hole will give you a consistent diameter all the way through the material, while an end mill deflects slightly and creates a tapered hole. Also, for a high volume of holes, using a drill is much faster. If you need to a deep hole, sometimes a drill is your only option due to the longer cutting lengths.

Drill

Our drills have micro-grain carbide tips and two flutes which are designed for machining in one downward direction only. These long-life tools are available in various cutting diameters, lengths and shank diameters.

Accessories

Vacuum Cards

The Vacuum Card serves as a sacrificial layer during machining operations on our DATRON vacuum tables. The engineered structure of the Vacuum Card distributes the vacuum evenly ensuring uniform holding force even when machining into the sacrificial layer by minimizing vacuum losses.

Adapter Insertion Tool

Open tool adapters for insertion of cutting tools using this simple to operate hand tool. Simply press the device handles together and a wedge like pin gently opens the spring-loaded adapter, allowing insertion of the cutting tool.

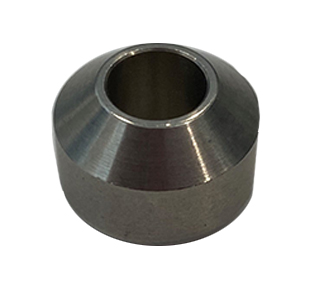

Tool Adapter

For speed and efficiency, make automatic tool changes from one tool shank size to another without changing the spindle collet. Attach an adapter quickly and easily to a tool shank using a special tool that opens the spring tensioned sleeve. The adapters come in a series of sizes for a range of tool shanks and spindle collet diameters.

Stop Ring Setting Tool

For press fitting the stop rings onto a tool shank, DATRON has developed this easy to use setting tool. Simply place the tool and ring into the device and hand turn the knob. There are two sizes available for 6mm and 8mm stop rings.

Stop Rings

To maintain precision cutting depths of direct shank clamped tools, a stop ring is required on the tool. This is so it can register against the spindle collet face consistently. The brass rings press fit onto the tool shank for a secure, one-time use. The larger dimeter rings use a set screw for clamping and can be used multiple times.

Conical Insert

For tables without the conical system, you can purchase the counterpart to the conical insert for building your own palletized mounting system. The inverted cones simply mount within the baseplate and have M6 threaded holes for the mounting of changeable pallets.

HSK E-25 Tool Holder

Machine with ultimate precision using Tribos polygonal toolholders. The HSK E-25 clamping technology has a concentricity (run-out) of <0.003mm required for micro machining. The holders have minimal vibration and come in a wide range of sizes and configurations. The Tribos SVP-2 unit is required to clamp and release tools.