CNC Cutting Tool Selection Guide

Selecting the right cutting tool for your CNC machine, material, and type of milling can make all the difference with both the time and quality of the results.

Learn about the different kinds of router bits used in CNC machines and how to choose the best milling tool for your operation.

End Mills

End mills are the work horse tools of CNC machining and there are different types of end mills and designed to cut sideways along the X-axis using cutting flutes.

END MILL BUYING GUIDE TIPS:

- Less Flutes = more material removal and less heat. More Flutes=finer finishes, but slower speeds and more heat.

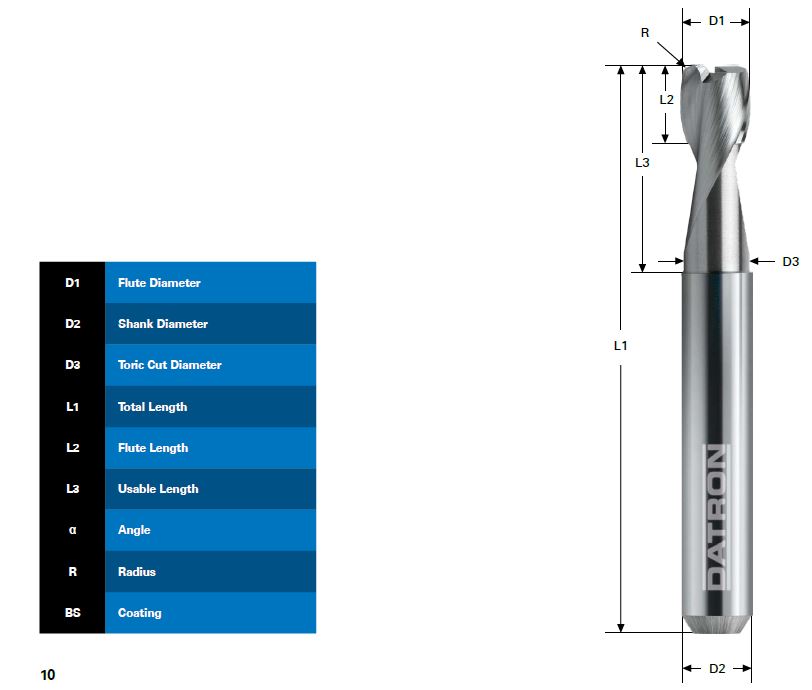

- For fastest milling use a short flute length L2 and larger flute diameter D1.

- If cutting materials other than aluminum you will want a mill designed for that material. Tools are available for cutting hard steel, foam, acrylic and plastics, carbon-fiber and composites, various other metals.

Single Flute End Mills

The single flute is designed to remove materials at high speeds. Having only one cutting flute allows more material to be removed per revolution of the bit and also prevents overheating. This makes this an essential milling tool and is typically the first bit used when machining.

Best For: Fast material removal and general milling.

Not Ideal For: Very fine or polished finishes.

Double Flute End Mills

Double flute tools are ideal for machining when surface finishes are important. They are typically used for finishing pockets and making lighter cuts. Also, they can be used in applications with tiny diameters because the double flute is stronger compared to a single fluted tool.

Triple and Four Fluted End Mills

Ball Nose End Mills

Ball nose end mills are designed for machining three dimensional contours and five-axis parts. The tools are ideal because the rounded cutting edge offers very little chipping and smooth surfaces.

External Radius Mills

Edge radius tools can machine a pristine radius along a workpiece edge or internally within a contour. These long-life, micro-grain carbide tools are available in various radii, shank diameters, and geometries for specialty applications

Specialty End Mills

Unique applications and situations often require very specific and special tools. We have developed a line of cutters to meet the requirements. These long-life, micro-grain carbide tools are available in various cutting diameters and lengths, shank diameters and geometries for the most demanding applications.

Micro-Toothed End Mills

If you need to machine, hard, glass-fiber like materials and required extended cycle times or tool life, these x.ceed and diamond coated micro-tooth end mills are ideal. These tools are designed to machine abrasive materials such FR4 or other printed circuit board like materials. The serrated tool can plunge cut as well as machine in X & Y directions.

Dovetail Milling

The dovetail milling tool is a chamfering tool that can create a bevel or relief on the underside of your stock material. For example, if you have a flat piece of aluminum secured on a vacuum table, you can deburr the underside using this tool without flipping the part and doing a second operation.

T-Slot and V-Slot Mills

If you need to machine an undercut, we offer a range of various sized T-Slot End Mills. This tool is not designed to plunge cut, therefore you are required to machine a pocket first, before contouring with the cutter. These tools are perfect for aluminum, brass, plastics, exotic composites and any soft metals. They are not recommended for steel.

If you are required to machine a 60, 90 or 120 degree channel on a surface, we have a line of V slot cutters to support this application. These tools can machine in all three directions. The tools are suited for aluminum, brass, plastics, exotic composites and any soft metals. They are not recommended for steel.

Countersink & Chamfer Mills

Tools that can drill a countersink in a single plunge or mill a chamfered edge.

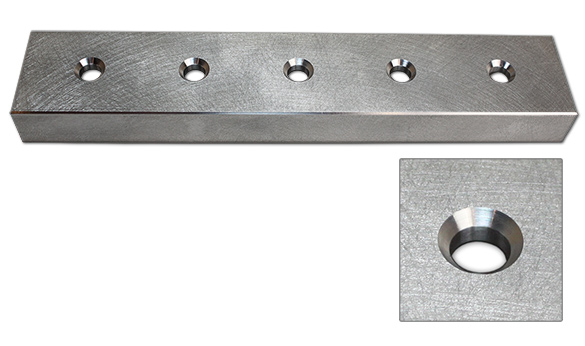

What Does a Countersink / Chamfer Mill Do?

Specially designed mills for cutting a small recessed beveled hole at the surface of drilled holes for allowing a screw to recess below or flush with the surface plane. These countersink mills will cut the hole and debur it for a clean countersunk hole that will not damage the drilled hole.

Engraving Tools for CNC

For precision, high-quality engraving, using engraving tools are recommended. The ‘V’ shape design allows you to machine very finite detail while still maintaining a good degree of strength in the tool. The cutting edges have a draft angle depending on the cutter which in most cases is desired for the end product.

Face Mills

BEST FOR: Face mills are designed to remove a skim coat off the top of a surface. Very effective in truing up your material or quickly providing an excellent surface finish

NOT RECOMMENDED FOR: They generally are not designed for roughing.

Thread Mills

For machining threads, these thread mills cover both ranges of Metric and Imperial sizes.